Email:

daylehe@jiliclean.com

|Moblie:

0755-27330235

|

中文

|

中文

|

English

English

CLOSE

Email:

daylehe@jiliclean.com

|Moblie:

0755-27330235

|

中文

|

中文

|

English

English

CLOSE

Label printing and processing is a growing market for static elimination. This is mainly due to the continuous increase in synthetic materials and UV inks and machine speeds.

UV ink

●The key is that the printing substrate must not be dusty when printing with UV ink, otherwise, there is a real risk that the product will be scrapped or misprinted and missed.

●The dust removal equipment installed after unwinding is not enough to cope with these problems.

●The substrate is usually charged with static electricity after passing through each printing station, and it gradually accumulates, and at the same time becomes the target of accumulation of dust particles in the air.

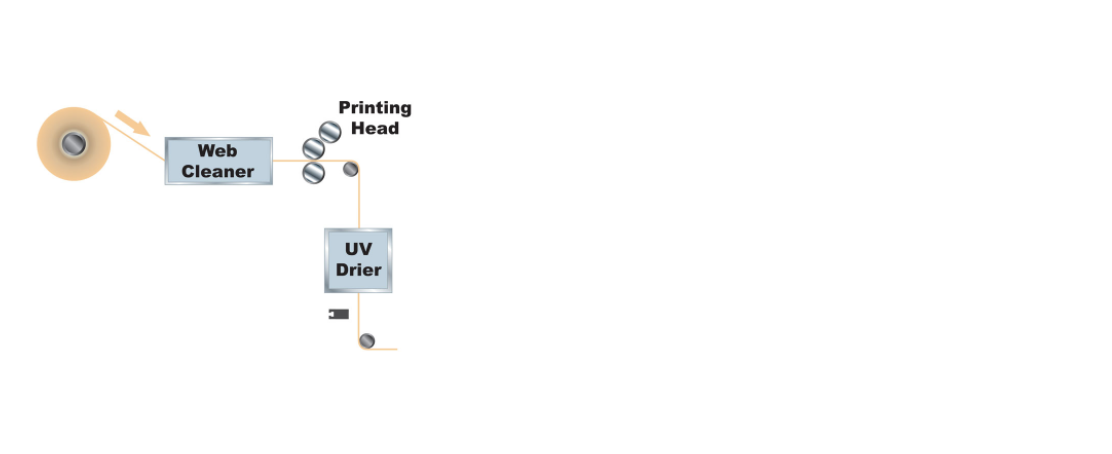

●We recommend that the installation position of the electrostatic bar is after the dust removal system and before the first printing unit. As shown in the location.

●The second static elimination bar is best installed after each UV drying device (see above picture) to eliminate any accumulation of static electricity before reaching the next printing unit.

The B-205 electrostatic bar is very suitable for installation on label printing machines. B-205 is an AC electrostatic rod with compact appearance, firm structure and easy to clean. It is very suitable for the installation of multiple rods at close range. The B-205 electrostatic rod is a very cost-effective choice, once installed, the effect will be significant.

标签: